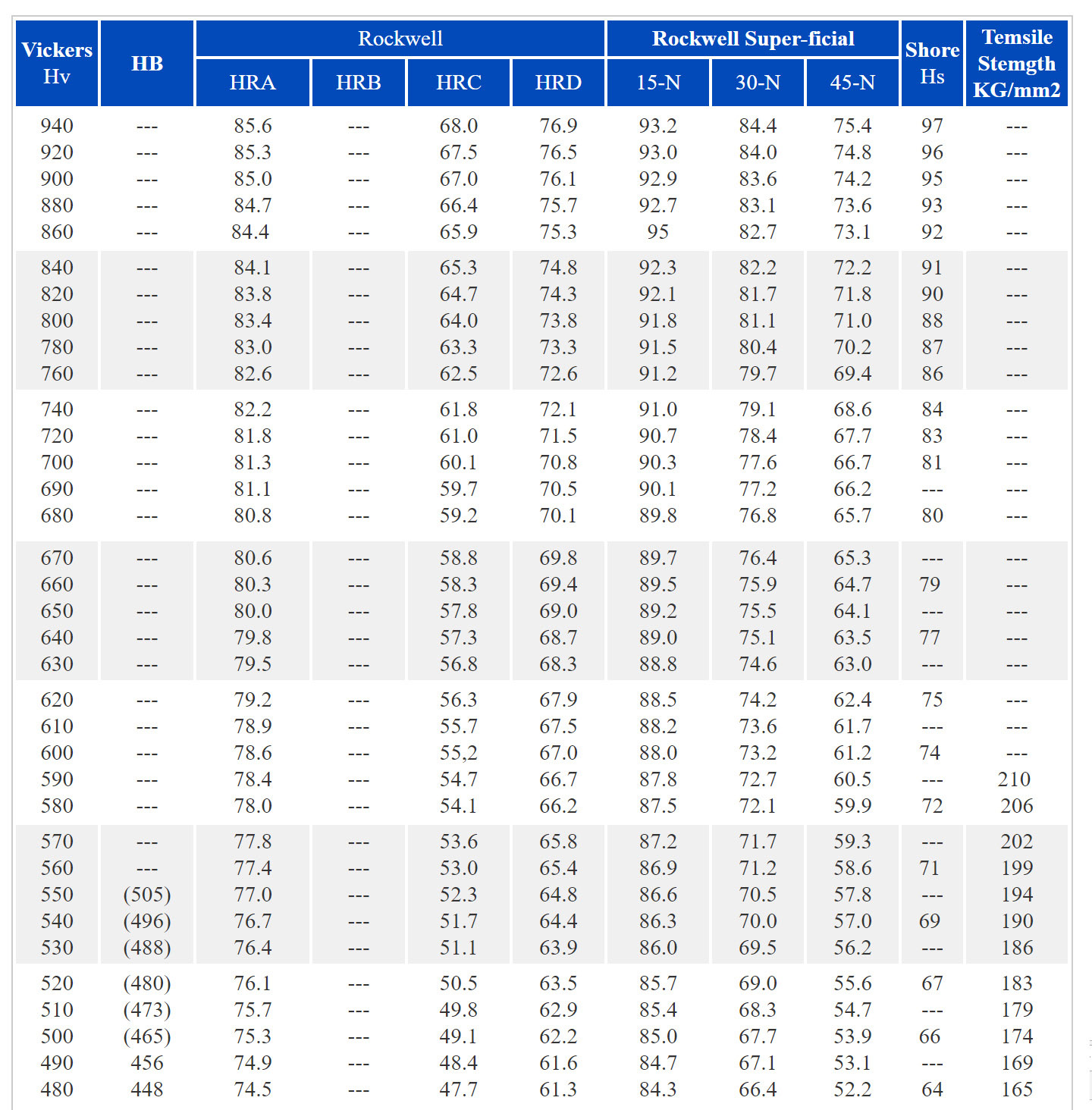

Rockwell Hardness Chart For Metals

Rockwell Hardness Chart For Metals. Rockwell Hardness Number: Rockwell Superficial Hardness. Due to different indenters, loads, and load durations, there are a variety of indentation hardness, mainly Brinell hardness, Rockwell hardness.

Due to different indenters, loads, and load durations, there are a variety of indentation hardness, mainly Brinell hardness, Rockwell hardness.

Tempered and Specialty Metals is one of the steel industry's most respected service centers and premier source for tempered stainless coil.

A value will always be higher on soft metal test subjects than hard metals. ROCKWELL SCALE ROCKWELL SUPERFICIAL BRINNELL Tensile Strength PSI RCD Custom Machinery Mainly used for metal materials, the method is to press the specified indenter into the material under test with a certain load, and compare the softness and hardness of the material under test with the local plastic deformation of the material surface. Since the various types of hardness tests do not all measure the same combination of material properties, conversion from one hardness scale to another is only an.

Rating: 100% based on 788 ratings. 5 user reviews.

Randy Hewes

Thank you for reading this blog. If you have any query or suggestion please free leave a comment below.

0 Response to "Rockwell Hardness Chart For Metals"

Post a Comment